Home Designer How to Use to Exterior Wall Sidings

Advanced Framing: Insulated Interior/Exterior Wall Intersections

Scope

Construct framed walls using advanced framing details like framing aligned at interior/exterior wall intersections to reduce thermal bridging and allow more space for insulation.

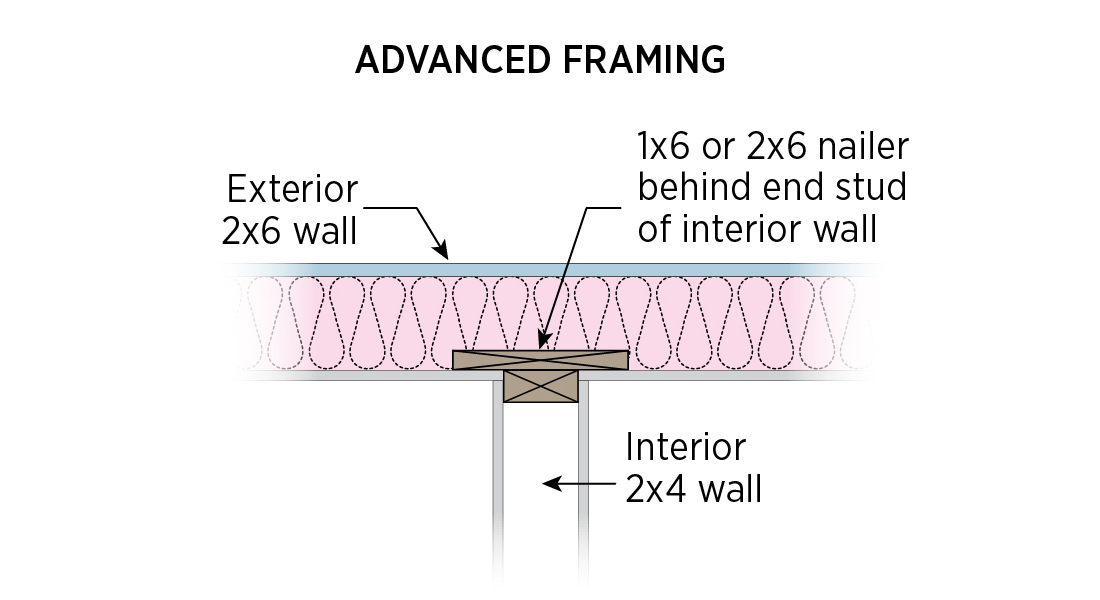

- Allow room for insulation at interior-exterior wall intersections by installing ladder blocking, a full-length 2x6 or 1x6 nailer behind the first partition stud, or connecting the interior partition stud to the exterior top plate using a flat metal connector plate and using drywall clips to attach drywall.

- Fill exterior wall cavity space behind intersection with wall cavity insulation to full R value.

See the Compliance Tab for related codes and standards requirements, and criteria to meet national programs such as DOE's Zero Energy Ready Home program, ENERGY STAR Certified Homes, and Indoor airPLUS.

Description

In stud-framed walls, where interior walls meet exterior walls, builders will typically use a conventional T-post detail. They will install two studs on the exterior wall, either touching each other or a few inches apart, at the location where the interior wall touches the exterior wall. The 2x4 stud at the end of the interior wall section is attached to these studs. If a few inches of space is left between these two exterior wall studs, insulation can be inserted in this space from outside before the exterior wall sheathing is installed; however, in practice the space rarely gets filled with insulation. This conventional framing method leaves uninsulated sections of exterior wall 3 to 6 inches in width everywhere an interior wall intersects an exterior wall.

Advanced framing techniques are described below that can be used to enable the installation of insulation along the exterior wall at the interior-exterior wall intersection.

These are some of several advanced wall framing techniques that can be employed by builders to increase energy savings by increasing insulation and reducing thermal bridging. Advanced framing also reduces costs by reducing lumber usage, materials waste, and labor time. See Minimum Wall Studs for more about advanced framing and for details on stud spacing and single top plates. Other advanced framing techniques are described in Insulated Corners, which explains how to construct corners with 2 studs instead of 3 studs to permit more insulation at the corners, Insulated Headers, which explains how and when to build open and insulated headers over windows and doors, and Minimal Framing at Doors/Windows for efficient framing around doors and windows.

Advanced framing techniques should be specified in the framer's contract. Detailed framing elevations should be prepared after confirming permissibility in the local jurisdiction.

How to Install Advanced Framing at the Interior-Exterior Wall Intersections

There are three options: ladder blocking, use of a support post, or use of a connector plate and drywall clips.

1. Ladder Blocking

- Install short sections of 2x4s horizontally between the studs on the exterior wall on each side of the interior-exterior wall intersection. Install them flush with the interior surface of the exterior wall studs at a spacing of 24 inches apart.

- Attach the 2x4 interior wall to these blocking pieces.

- Install insulation behind the blocking.

2. Support Post

- Install a 1x6 or 2x6 support post on the exterior wall at the interior wall location, flush with the interior face of the wall. Attach it to the top plate and bottom plate.

- Attach the interior 2x4 wall to it.

- Insulate behind the post.

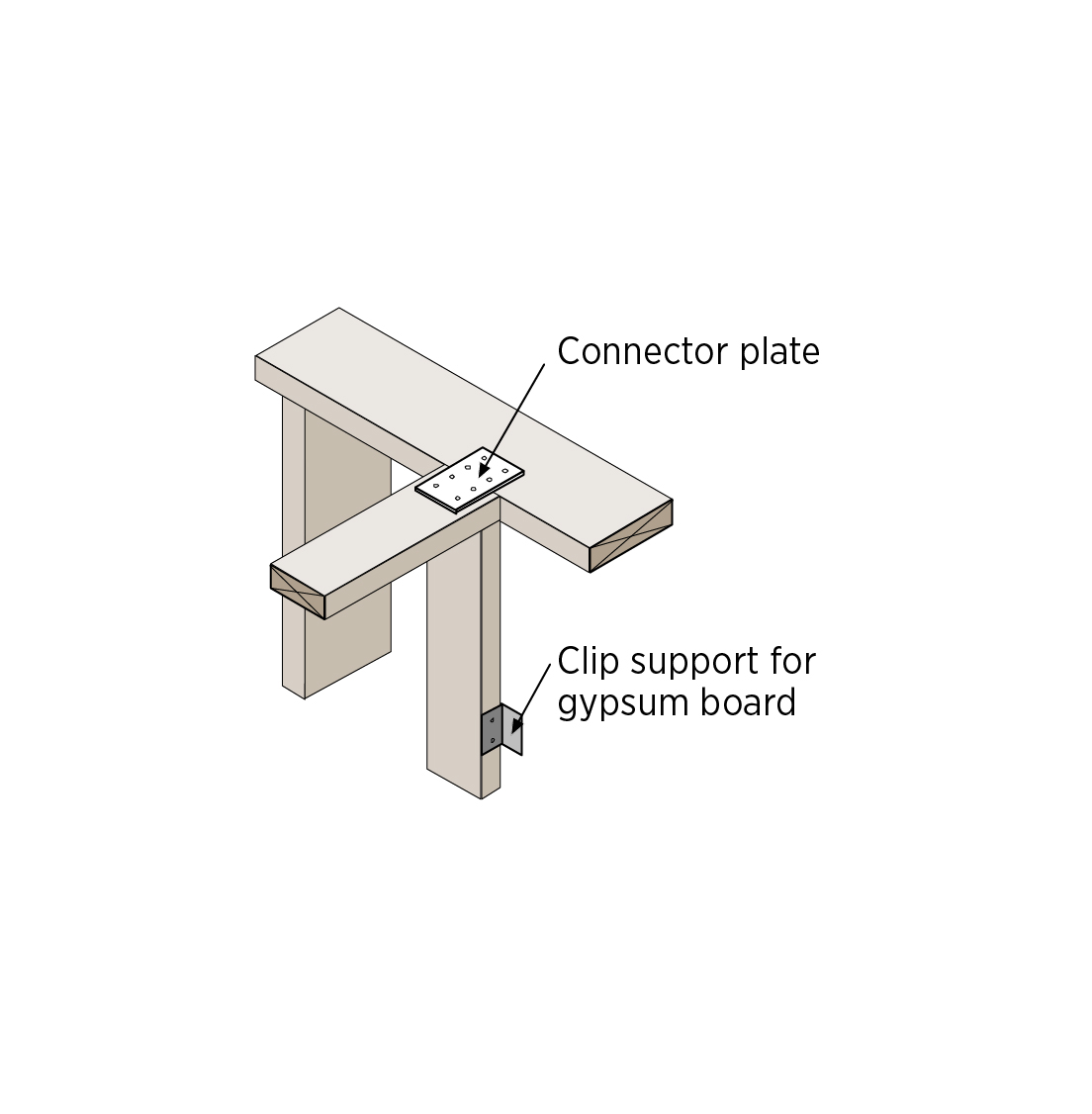

3. Connector Plate and Drywall Clips.

- Attach the interior 2x4 wall to the exterior wall top plate with a flat metal connector plate. Toenail the interior stud directly to the bottom plate.

Figure 6. Connector plate and dry wall clips. - Attach dry wall clips to the end stud of the interior wall to support drywall.

- Insulate behind the post.

Ensuring Success

Advanced framing details should be specified in the construction plans and reviewed with framers. The construction supervisor should ensure that framing crews are knowledgeable of or trained in advanced framing techniques. The framing should be visually inspected by the site supervisor before the drywall is installed.

Climate

No climate specific information applies.

The Compliance tab contains both program and code information. Code language is excerpted and summarized below. For exact code language, refer to the applicable code, which may require purchase from the publisher. While we continually update our database, links may have changed since posting. Please contact our webmaster if you find broken links.

ENERGY STAR Certified Homes, Version 3/3.1 (Rev. 09)

National Rater Field Checklist

Thermal Enclosure System.

3. Reduced Thermal Bridging.

3.4.3d Interior / exterior wall intersections insulated to same R-value as rest of exterior wall.24

Footnote 24) Insulation shall run behind interior / exterior wall intersections using ladder blocking, full length 2x6 or 1x6 furring behind the first partition stud, drywall clips, or other equivalent alternative.

Please see the ENERGY STAR Certified Homes Implementation Timeline for the program version and revision currently applicable in in your state.

DOE Zero Energy Ready Home (Revision 07)

Exhibit 1 Mandatory Requirements.

Exhibit 1, Item 1) Certified under the ENERGY STAR Qualified Homes Program or the ENERGY STAR Multifamily New Construction Program.

Exhibit 2, Item 2) Ceiling, wall, floor, and slab insulation shall meet or exceed 2015 IECC levels and achieve Grade 1 installation, per RESNET standards.

Access to some references may require purchase from the publisher. While we continually update our database, links may have changed since posting. Please contact our webmaster if you find broken links.

References and Resources*

*For non-dated media, such as websites, the date listed is the date accessed.

Contributors to this Guide

The following authors and organizations contributed to the content in this Guide.

Mobile Field Kit

The Building America Field Kit allows you to save items to your profile for review or use on-site.

Sign Up or Log In

Did you find this information helpful?

Home Designer How to Use to Exterior Wall Sidings

Source: https://basc.pnnl.gov/resource-guides/advanced-framing-insulated-interiorexterior-wall-intersections

0 Response to "Home Designer How to Use to Exterior Wall Sidings"

Enregistrer un commentaire